How does the chemical stability of ABS 3D filament support its long-term use in complex environments?

Publish Time: 2025-11-24

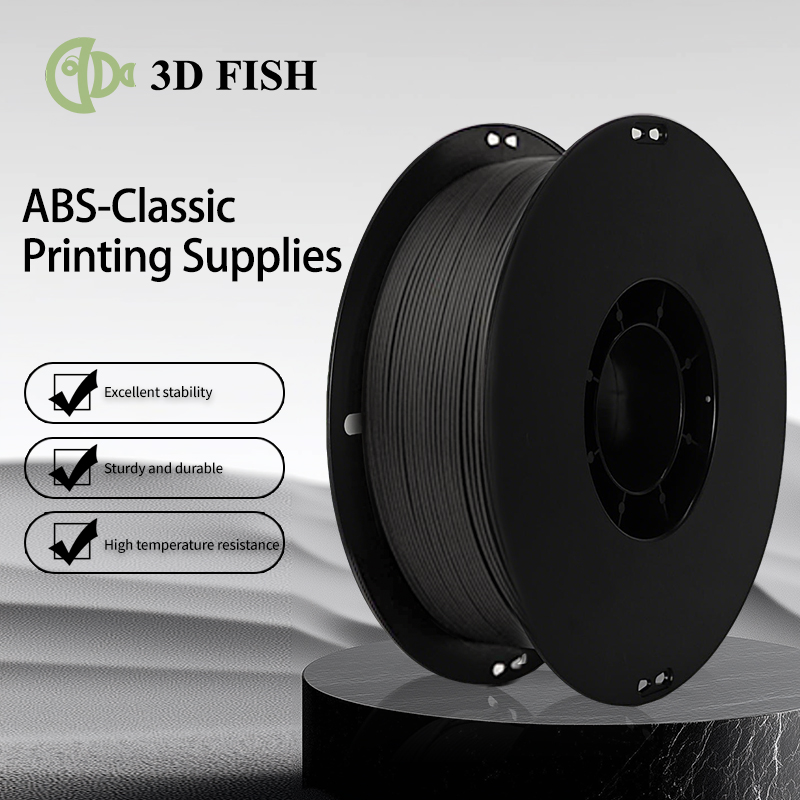

In industrial manufacturing, automotive parts, consumer electronics, and even functional prototyping, ABS (acrylonitrile-butadiene-styrene copolymer) has always held an important position as one of the earliest and most widely adopted engineering-grade 3D filaments. Its popularity stems not only from its good mechanical strength and heat distortion temperature, but more importantly, from its excellent chemical stability—a characteristic that allows it to maintain structural integrity and functional reliability even when faced with complex chemical environments such as oil stains, weak acids and alkalis, cleaning agents, and solvent vapors, thus supporting long-term, stable application performance.I. Molecular Structure Lays the Foundation for Chemical ResistanceABS's excellent chemical stability originates from its unique ternary copolymer structure:Acrylonitrile provides chemical resistance and rigidity;Butadiene imparts toughness and impact resistance;Styrene contributes good processability and surface finish.This synergistic effect enables ABS to exhibit good resistance to a variety of common chemicals. For example, at room temperature, it exhibits strong resistance to diluted inorganic acids, alkalis, alcohols, vegetable oils, mineral oils, and most salt solutions, and is not prone to swelling, embrittlement, or significant degradation. This means that housings, supports, pipe fittings, or tool clamps printed from ABS can maintain dimensional stability and mechanical properties even when exposed to coolants, lubricants, cleaning agents, or humid air, avoiding premature failure due to chemical corrosion.II. Real-world performance in industrial settingsIn real industrial environments, ABS components are often exposed to harsh conditions involving multiple stresses and chemical media. For example:In automotive repair shops, ABS-printed sensor housings may be in prolonged contact with gasoline vapor, brake fluid, or antifreeze;In food processing plants, equipment rails or sorting components are frequently subjected to chlorine-containing disinfectants or alkaline cleaning agents;In laboratory auxiliary equipment, supports or sample racks may be briefly exposed to ethanol, acetone, or buffer solutions.Extensive practical experience has shown that, as long as strong oxidizing acids, aromatic hydrocarbons, and halogenated hydrocarbons—the "forbidden solvents" for ABS—are avoided, it can operate stably for months or even years in the aforementioned scenarios. This "sufficient and reliable" chemical resistance makes it an ideal choice for functional components in non-extreme chemical environments.III. Comparative Advantages with Materials Like PLACompared to the more readily available PLA (polylactic acid), ABS has a significant advantage in chemical stability. While PLA is environmentally friendly and biodegradable, it is prone to hydrolysis in humid or weakly alkaline environments, leading to a sharp drop in strength; ABS, on the other hand, does not have this problem. Similarly, compared to flexible materials such as TPU, ABS performs better in resisting oils and solvents. Therefore, in applications requiring a balance of strength, heat resistance, and chemical resistance, ABS remains an irreplaceable engineering plastic option.IV. Post-treatment Further Enhances Protective CapabilitiesTo expand the applicability of ABS in more demanding environments, users can further enhance its chemical barrier properties through post-treatment methods. For example:Acetone vapor polishing creates a dense, smooth layer on the surface, reducing micropores and cracks and lowering the risk of chemical penetration;Spraying epoxy or polyurethane coatings creates an additional protective film, effectively isolating corrosive liquids;Vacuum impregnation sealing is suitable for printed parts with internal cavities, preventing moisture or vapor from penetrating the internal structure.While these processes increase the number of steps, they significantly extend the service life of ABS parts in chemical, marine, or outdoor environments.V. Design and Usage Recommendations: Leveraging Strengths and Avoiding Weaknesses for Safe ApplicationAlthough ABS has good chemical stability, it still needs to be used properly:Avoid prolonged immersion in organic solvents;In environments with high temperatures and chemical media, the risk of accelerated aging should be assessed;For food or medical contact scenarios, it is necessary to confirm that the ABS used complies with FDA or relevant biocompatibility standards.Through scientific material selection and standardized use, ABS 3D printed parts can achieve "long-term reliable service" in complex environments.ABS 3D filament, with its inherent chemical stability derived from its molecular structure, demonstrates strong environmental adaptability in numerous engineering applications. It's not a panacea for chemicals, but within its intended application—facing everyday industrial chemicals, cleaning agents, greases, and humid environments—it proves its value as a classic engineering plastic with robust performance. For users seeking a balance of functionality, durability, and cost-effectiveness, ABS remains a reliable 3D printing option for complex environments.